We came to Seattle, a small group representing the industry, from different parts of the globe and embracing a broad of disciplines. Amongst our number were pilots, cabin crew union reps, analysts, former regulators and accident investigators, consumer advocacy, writers and a nuclear physicist. Invited by Boeing to engage and discuss with the company’s leadership on what it is doing to achieve the safe return to service of the Boeing 737 Max and more broadly to restore trust in its culture and business ethos. This is my personal account and impressions of the visit. It is by nature subjective and I will focus primarily on the issues on which my experience allows me to provide an informed view and less so on the technicalities of piloting which others are better able to comment on.

Boeing is rightly in the spotlight following the two tragic Max crashes. I reflected deeply, taking counsel from trusted colleagues, before accepting. Everyone said “you must go” and I’m glad I did. The accidents certainly shook my faith in Boeing and led me to question how it could have got itself into such a position and whether it had lost its exemplary focus on engineering prowess.

An intense programme was provided over a long day and a half, including commentary on the company’s actions, factory visits, simulator time and most importantly extensive opportunities for questioning of the leadership team.

Boeing’s chief pilot Craig Bomben spent most of the first day with us, presenting & providing time on the E Cab Max simulator in the evening, allowing pilots to experience both old and new software linked to the MCAS system, implicated in the two accidents. Whilst much of his narrative addressed his own confidence in the proposed remedies for the Max (he piloted the aircraft’s first flight), he highlighted the need to collaborate and partner with other OEM’s at an industry level to learn lessons from these accidents and share best practise. As a result of the accidents he sees Boeing’s own pilots now having a much greater role in human factors training and cockpit design. Scenarios concerning pilot response times need to be rethought as they did not hold good in the two accidents. He acknowledged that some regulations are out dated and not now appropriate for modern aircraft and cautioned that “bubble wrapping” pilots with automation risks degrading skills.

I was particularly keen to hear from and put questions to CEO Dennis Muilenburg. In the 90 minutes that he spent with us, I gained a much stronger positive impression face to face, of genuine contrition, sincerity and willingness to take on board responsibility than had seemed apparent in media coverage. He is an engineer by trade, with Boeing for 34 years. “We want to get your help, advice, counsel and perspectives”, he told us. He apologised repeatedly and acknowledged that Boeing had been “slow to step up to total responsibility…we are responsible”. He talked about his meetings with families of the deceased and how hearing their stories has inevitably left their mark deeply for him personally. He acknowledged “fair criticism” and stated “we will never prioritise profits over safety”. He came to Boeing as an engineer believing in the mantra “connect, protect and explore the world “. He spoke of how the fabric of company culture has changed, only time will tell, but in the months and years ahead, I need to see that it has. He certainly provided comprehensive evidence of what has been done so far and what will be done. Safety starts at Board Level and the company is focussed on the principal of “safe airplanes, safe system”. A new integrated safety organisation has been established, led by Beth Pasztor, from whom we heard. All engineering functions have been consolidated via the Chief Engineer rather than being fragmented across different programmes. For the Max specifically, information is being added in manuals to reduce time spent by pilots diagnosing. Investment is being made in 35 Max simulators in Seattle to assist with expected pilot training requirements.

Muilenburg was emphatic that Boeing has “no interest in putting unsafe planes in the air” and for me his necessary recognition that “we made some mistakes and assumptions in the design process which had worked for years” and his acknowledgement that “we have damaged confidence in the pilot community”, were highly important statements. He also sees that for the flight deck of the future there is a need to revisit design assumptions in high workload situations.

Some pilots in the visiting group voiced a sense of betrayal, he took this on board “…we weren’t assertive enough early in the process, it is not our place to blame pilots“.

I put it to him that there are people in Boeing who have, by inference, blamed the pilots for these two accidents. His response was clear, “we will not blame pilots, I have told the team”. A clear leadership direction but it needs to be embedded firmly in company culture.

I questioned him about the challenge of operating in a globally competitive market, dealing with hard-nosed airlines demanding ever keener deals on pricing and necessitating cost cutting. How does that stack up against safety culture? “I’m not gonna say we aren’t taking costs out, we are.” This will never be at the expense of safety he said, citing the 737 Max production rate cut as an example of how they are using the opportunity to improve processes.

I also asked him how he saw the regulatory challenge of getting the Max back flying again safely and what it might mean for future aircraft certification. He sees the need for a global ungrounding, though he expects some time phasing and warns that “we don’t want to see a future of fragmentation, that’s bad for safety. We need a safety management system that is integrated, best practice”. I’d concur with that.

How to sum up the time he spent with us? Sincere, focussed, in his words “humble…room to improve and we want your advice”.

We heard from Beth Pasztor, Boeing’s new VP Product and Services Safety. I was pleased to learn she’s another engineer “lifer”, with 34 years service. She worked on the 747-400 programme and the challenges its new central maintenance computer presented. I told her that while she was doing that, I was coming up with numbers for a compensation claim from BA for delayed delivery of our first 400’s! I was very encouraged listening to and speaking with her. She is there to provide an independent voice and to foster both anonymous and named reporting, encouraging employees to speak up with confidence, on anything they believe to be detrimental to safety. I asked her if she is confident that this can really happen and whether employees can feel free of “undue pressure” not to report problems or to comply? She highlighted that this is about management style, refreshing the focus and checking the culture. It’s also important that new employees, who may not have witnessed accidents and setbacks, benefit from the experience of those that have. She highlighted that while there must be a safety culture, it also needs to be a just culture where people feel they can speak up. She also talked of the need for the industry to come together holistically on safety. I found her both authoritative and highly credible. Current and future Boeing management must walk the talk, not only supporting the organisation that she has been tasked with leading, but giving it teeth too.

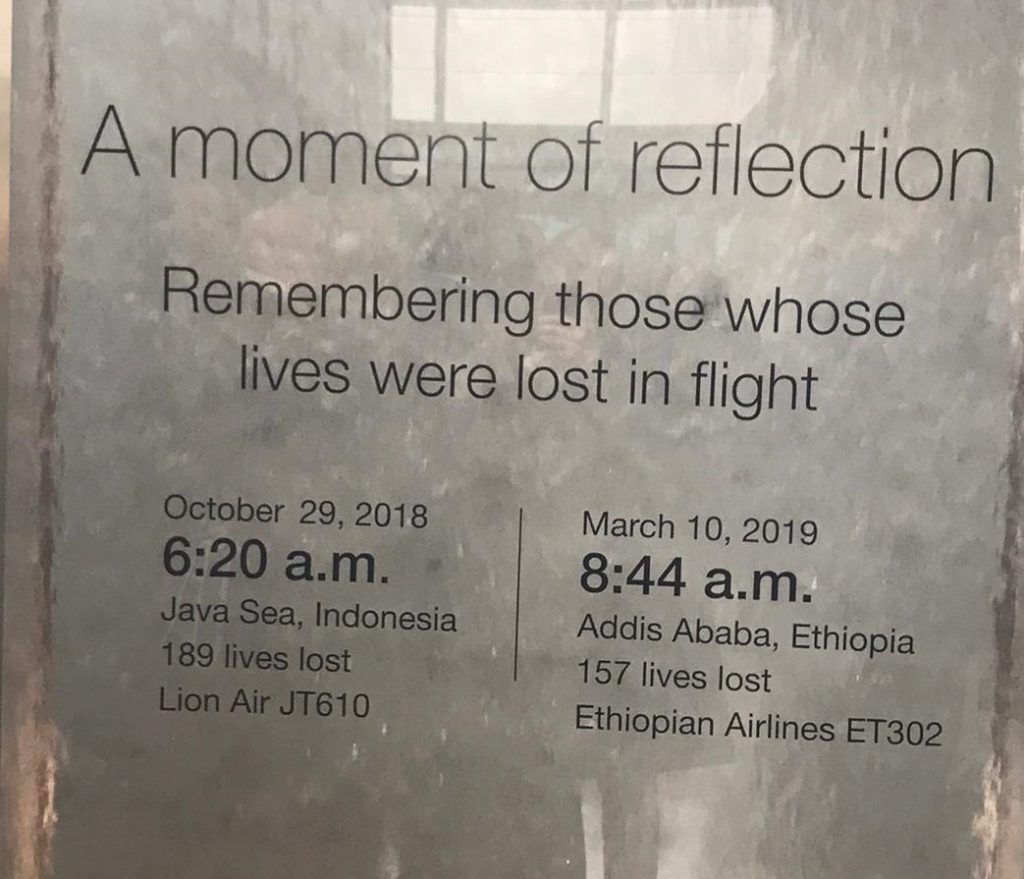

Reflecting more broadly on safety culture, we visited Boeing’s Safety Promotion Centre at their Everett plant. This exhibit has existed for around three years and is primarily focussed on an internal audience. It was inspired by a similar centre established by JAL after the fatal crash of one of its 747’s in 1985. It tells the story of how aviation safety has evolved through the decades and how lessons are learned from every accident, it is led by Boeing’s chief accident investigator, Richard Anderson. There is a poignant tribute to the lives lost in the two Max accidents and Muilenburg wants to ensure that every single Boeing employee visits the centre.

While Boeing is in the hands of regulators as to when, assumedly, the Max returns to service, we heard from Mike Fleming, Vice President of Commercial Services for Boeing Global Services who is leading the complex task of doing so.

With around 800 aircraft either manufactured, delivered, preserved or stored, RTS (return to service) has to be managed on a tail by tail basis. Boeing knows the condition of every single Max aircraft worldwide and under what conditions they have been stored or preserved and consequently what is required to de preserve each one for RTS. While the company hopes that RTS will be early in the New Year, it recognises that even after a regulatory green light, it will take “multiple quarters” and a ramping up in deliveries to achieve this for the entire global fleet. A dedicated Operations Centre has been set up in Seal Beach California to provide 24/7 engineering and supply chain support along with a communications team to manage inevitable media interest. Boeing teams are working with each individual aircraft to ensure everything possible is done for a smooth return. The world will be watching.

The challenge of restoring travelling customers confidence and trust both in the Max and in the company is not underestimated by Boeing and how exactly this can be achieved is very intangible. For sure, the work has to start by winning back the hearts and minds of the world’s pilots and cabin crew. Several of their number were active members of the group and they have to be 100% confident. Talking to some of them on the visit, these two days in Seattle provided a good first step. Personally I am pleased Boeing reached out to engage, without limiting discussion or prescribing what they hoped the outcome would be. It will be the first of many steps. I was encouraged to see the recognition of mistakes and the need to own responsibility coming right from the top, there is no other way. I was heartened to see that engineering skill is immersed at the core of Boeing’s leadership team, that its importance is being consolidated and to see that real efforts are being made to ensure all employees are comfortable to speak out on safety concerns.

The 346 lives lost in the two Max accidents can never be brought back, the tragedies must never be forgotten but looking forward Boeing has to re-establish trust through its actions. Both it and the wider industry must be willing to collaborate and share the learnings which these events bring and to accept the need to challenge, adapt and change accepted methodologies in design, production, operational processes and training where it is clear that this will strengthen the industry’s safety imperative.

Interesting article John. One of the biggest challenges, you touch on at the end. How to gain the confidence of the pilots and crew BUT just as importantly the paying public. I.e. the pax. How do airlines and Boeing gain our confidence?